Ordering instructions.All non-quality problems of our products will not be returned.Sample of rubber ground rubberExpress delivery, multi-volume logistics. The goods only reach the local city-level freight department. If the logistics is convenient, you can go to the county-level city and then call you to pick up the goods. If you need to deliver, please contact customer service staff before buying(Or you can talk with local logistics after arrival). For logistics delivery, a reasonable delivery fee needs to be charged according to the local distance. The online price does not include freight, please consult customer service staff for details before placing an order.(For customers who do not contact customer service and place an order by themselves, the fee will be paid in full and will be charged according to the actual).

Regular manufacturers can produce formal invoices, subject to 6% tax, customers who need to invoice need to contact customer service in advance, or leave a message to explain, without remarks, we will default that you do not need invoices.

Product specifications: 50 * 50 * 1.5cm 1 square weight about 15.2KG

Product specifications: 50 * 50 * 2.0cm 1 square weight about 19.2KG

Product specifications: 50 * 50 * 2.5cm 1 square weight about 22KG

Product specifications: 50 * 50 * 3.0cm 1 square weight about 26KG

Product specifications: 50 * 50 * 4.0cm 1 square weight about 34KG

Product specifications: 50 * 50 * 5.0cm 1 square weight about 42KG

Installation process:

1. Clean up the site

Dust removal and cleaning: Before the actual pavement, clean the pavement and clean it, especially to check whether the pavement has cement mortar dripping from civil engineering and oil pollution caused by oil leakage from paver and roller. The cement floor should be air-dried, flat, without convexity, and flat.

2. Laying safety mat

(1) According to the size of the venue, arrange an appropriate number of people to go to lay;

(2) After entering the site, determine the accurate, material-saving and labor-saving method according to the requirements of the drawings and the actual site;

(3) Find three suitable edges on the site, use a white line horizontally one horizontally and two vertically and extend to cross it at a right angle, the distance between the horizontal and vertical white lines from the edge of the site(Maximum distance)It is suitable for 49.549CM. In order to make the mat contact with the surroundings after being extruded, it is tight and seamless;

(4). Arrange one person to apply special special glue horizontally in the white line from left to right, and arrange another person to lay the safety mat in sequence. Both horizontal and vertical directions are overlapped forward and left when every three pieces are laid 0.5-1CM(According to the thickness of the mat)So that when squeezed, the safety mat can be laid tightly without gaps in the middle;

(5) When applying glue, it should be applied to the four corners and the middle of each mat, with an area of about 10CM in diameter;

(6)1. After laying for about an hour or so, start squeezing the first safety mat to be laid out.(Subject to white line)Position with cement nails so that the mat does not shift when squeezed.

(7)1. Use a rubber hammer when squeezing. Do not knock down the floor mat to ensure that the floor mat is complete and intact. Also, ensure that the floor mat is lined up side by side, straight and diagonally at right angles. phenomenon;

(8)1. After laying the white line with the above method, if you need to cut the remaining four sides, pay attention to cutting into slopes.

Cut less, cut more at the bottom.

(9)1. There is key body equipment in the laying process, and the pipe of the fitness equipment should be compared with the drawing to cut the safety mat, leaving a gap to install the fitness equipment, the cutting method is the same as above;

(10)3. After all the laying is completed, clean up and sweep the site, and pass the inspection and acceptance.

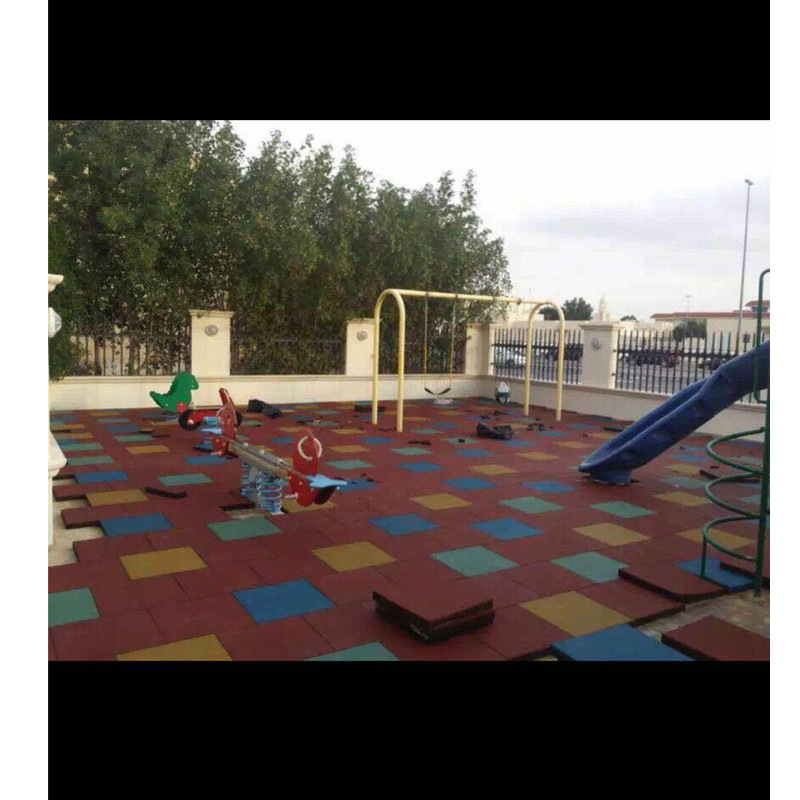

Factory direct rubber floor mat

Gym rubber floor cushion cushion

Manufacturers supply outdoor mat

Thickened plastic mats, kinderga

Yoga special rubber floor mat ru

Supply 1.5cm thickness rubber fl

Kindergarten Safety Mats Huadu Z

Rubber floor manufacturers, gym